Is a fully-automized Rolling Mill situated at Sodepur in the district of 24 Parganas North, which manufactures Wire Rods in coils and TMT bars.

Earlier being the largest conversion agent for Tata Steel/SAIL in eastern India. We were also the conversion agent of BHEL during 1990.

We are an "A" class Mill and the holder of ISI/BIS, a self - certifying license. We issue test certificates conforming to IS I786 FE 415 and FE 500 grade. Pedigreed prime Billets of IS 2830 which have a carbon content of only 0.15% with low sulphur, manganese and phosphorous is used during the manufacturing process.

Before rolling, the billets need to be approved by our quality management team which is done at our chemical laboratory.

The physical testing laboratory ensures the following properties to be in the correct proportion before issuing the Test certificate.

Dimension of bars, Bond strength, Proof stress, Bendability, Elongation, Ultimate Tensile strength, Grain structure and Weldability.

The steel bar ought to be ductile (soft) but hard enough to maintain the design. This is only achievable in an automized controlled mill but one can find the same in AHW Steels Ltd.

We strive to maintain lower weight as per ISI, enabling customers to save on costs as the use of bars is always done on a length basis thus making them buy lesser tonnage.

is a fully automized rolling mill situated at sodepur, in the district of 24-parganas(north), producing the entire range of SHAN brand under Thermex License and wire Roads from pedigreed prime billets conforming to lS:2830.SHAN brand of TMT Bars follows the BIS standard, conforming to lS:1786 of FE-415 and Fe-500 grade, sizes of shan brand of TMT bars range from 6-16 mm.

The techonology involved and stringent quality testing parameters are comparable to the best infrastructural facilities as well production practices in the industry. The manufacturing, quality testing, packaging and despatching of materials are executed by satisfying al relevant high-end technical parameters under strong supervision, ensuring utmost customer satisfaction.

The marketing team of SHAN TMT and wire Rods comprises of quality professionals. The team guarantees ethical and transparent trade practices, aggressive brand promotion and efficient after-sale services.

Coming from the house of quality steel Makers since 1952, we at SHAN family strive to establish ourselves as a brand to reckon with.

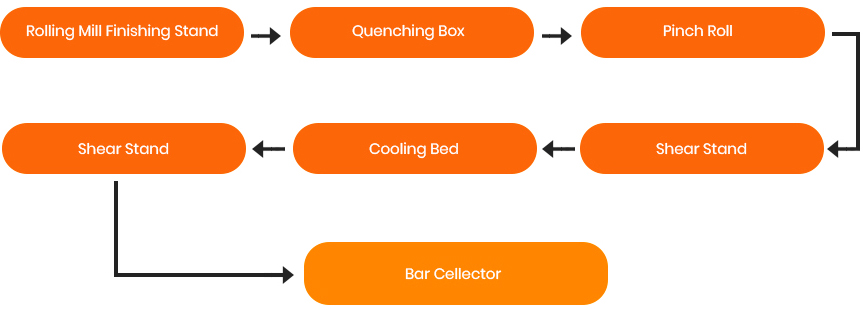

Production Process Flow Chart

The advantages of Shan (Thermex) - TMT Bars over Conventional TMT Bars are as follows:

Enhanced Strength

Enhanced Strength High Ductility

High Ductility Superior Atmosphere and Marine Corrosion Resistance

Superior Atmosphere and Marine Corrosion Resistance Good Weldability

Good Weldability No loss of strength at welded joint

No loss of strength at welded joint Better High Temperature Thermal Resistance

Better High Temperature Thermal Resistance Easy Working at site

Easy Working at site Better Ductility

Better Ductility Better bendability

Better bendability Better Rebendability

Better Rebendability Better Seismic and Wind load Resistance

Better Seismic and Wind load ResistanceWe are selling our products to our distribution network, Govt. departments like the Indian Railways, MES, CPWD, P&T, PWD, Irrigation Department and major construction projects. Our main focus is to market our premium quality brand at a reasonable price to our esteemed customers.

Our distribution channels encompasses West Bengal and North Eastern states. Our distributors are reputed business houses in construction and building materials industry, with strong financial status, solid infrastructure, supportive sales personnel and excellent network of dealers and retailers.

We are also targeting foreign markets like Bangladesh, Srilanka, Vietnam, Mayanmar, Nepal, Bhutan and African countries.

We have a well planned advertising campaign that helps us promote our brand in the market. Our sales team compromises of experienced and energetic professionals, who keep themselves updated with the market development. We are renowned for our after sale services in terms of efficiency and timely delivery.

Shyamkunj, 6th Floor 12C, Lord Sinha Road

Kolkata- 700071, India